CLEANING IN PLACE

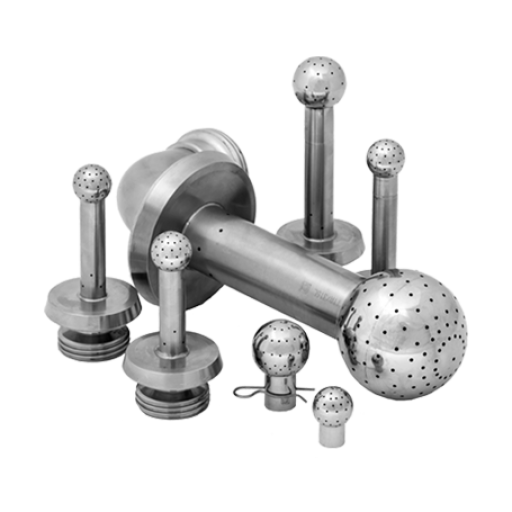

Cleaning of your production line must be very adequate yet easy. Protection of your product safety is priority. Cleaning-in-Place (CIP) offers the solution. TFT provides two possibilities: either an integrated CIP-pump in the tempering/aeration system, or a single, central machine to auto-clean several process lines. We have taken great care of the design of all cleaning equipment. Materials and surface finish are up to FDA standards, guaranteeing no residue is left behind. The integrated CIP-pump in our systems creates a turbulence at high velocity in the pipe work and equipment. When you have a number of machines that need to be cleaned, a central, multi-functional CIP system is interesting. Our CIP system prepares the cleaning liquid in advance and auto-cleans the various process lines.

Executed with PLC and HMI touch screen and equipped with an automatic self-cleaning cycle so the CIP unit cleans itself when necessary. TFT central CIP systems consist of:

- pre rinse tank, single walled

- cleaning tank, insulated, with heating

- final rinse tank

- steam heated plate heat exchanger, to heat up water in the cleaning tank

- detergent injection system with measuring sensor

- disinfectant injection system with measuring sensor

- high velocity CIP pump, to supply possible various process lines

- high velocity CIP return pump, to return CIP water to the unit

- advanced programming